COMPANY NEWS

How to Clean Anilox Rollers Without Damage? — A Must-Read Guide for Printing Companies

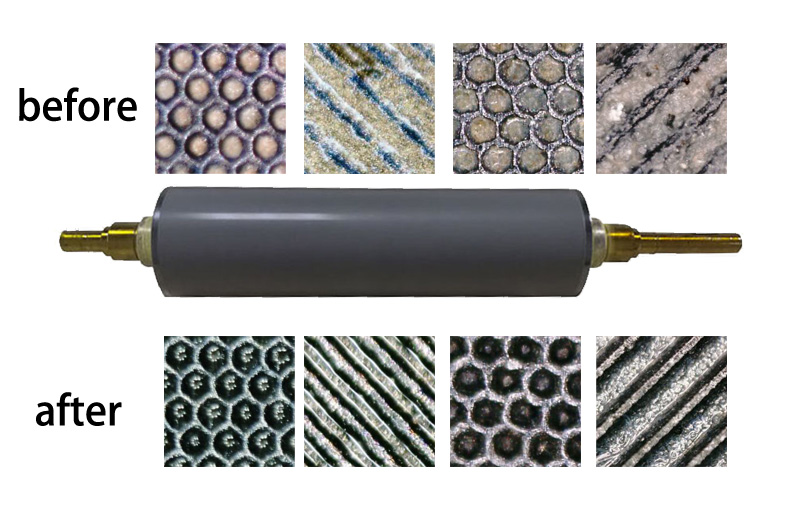

In flexographic printing, gravure printing, and the packaging industry, the anilox roller is one of the core components. It determines the precision of ink transfer and the overall print quality. However, after long periods of use, dried ink and impurities tend to accumulate inside the cells. If not cleaned properly, this not only affects the printing result but also shortens the service life of the roller. So, how can you clean anilox rollers without causing damage? This article provides a detailed.

Why Do Anilox Rollers Need Cleaning?

Maintain Ink Accuracy: Clogged cells cause uneven ink transfer, leading to color deviations.

Extend Service Life: Residual ink layers can corrode the surface and reduce roller lifespan.

Improve Printing Efficiency: Reduces rework and scrap rates, boosting overall productivity.

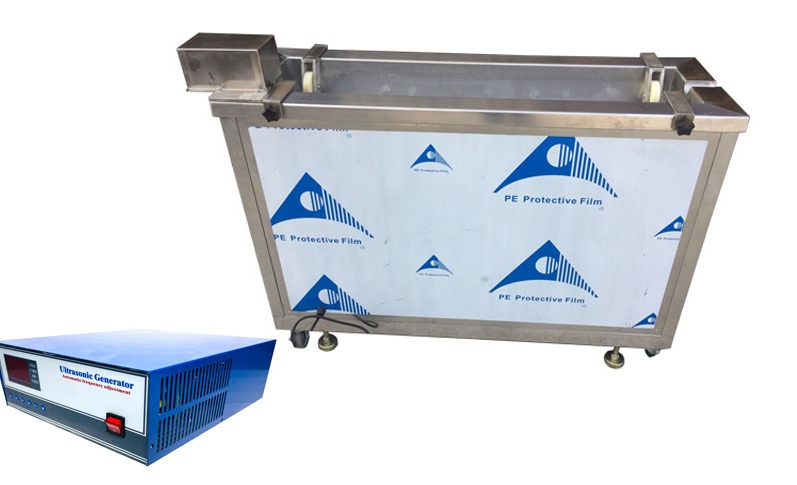

Ultrasonic Anilox Cleaning Machine (Recommended)

Principle: High-frequency ultrasonic waves generate cavitation effects in water, dislodging dried ink and impurities from the roller cells.

Advantages:

-

Non-Damaging: Does not harm the roller surface, preserving geometric accuracy.

-

Thorough & Efficient: Cleans all the way to the bottom of the cells.

-

Eco-Friendly & Energy-Saving: No need for strong acid or alkali chemicals.

-

Wide Applicability: Suitable for ceramic anilox rollers, metal rollers, and roller sleeves.

How to Properly Use an Anilox Roller Ultrasonic Cleaner?

- Select the appropriate ultrasonic frequency (usually between 25–40 kHz).

-

Control cleaning time to avoid over-cleaning.

-

Use specialized eco-friendly cleaning solutions to enhance effectiveness.

-

Regularly maintain the cleaning equipment to ensure stable performance.

The Best Solution for Non-Damaging Cleaning

Ultrasonic anilox cleaning equipment have proven to be the best choice for anilox roller maintenance in printing enterprises. They not only remove ink residues thoroughly but also prevent the risk of damage from manual cleaning.

For businesses aiming to achieve high printing quality while reducing maintenance costs, investing in a professional ultrasonic cleaning system is a powerful way to boost competitiveness.

Conclusion

Anilox rollers are critical components in the printing process, and choosing a scientific, safe cleaning method is essential. Compared with chemical cleaning and sandblasting, ultrasonic cleaning is the truly effective solution for “non-damaging anilox roller cleaning.”

If you are looking for a reliable anilox roller ultrasonic cleaning machine, feel free to contact us. We will provide you with the optimal cleaning solution to help take your printing business to the next level.